Development of temperature-responsive cell culture dish “UpCell®”and the research promotion of next-generation platform technology

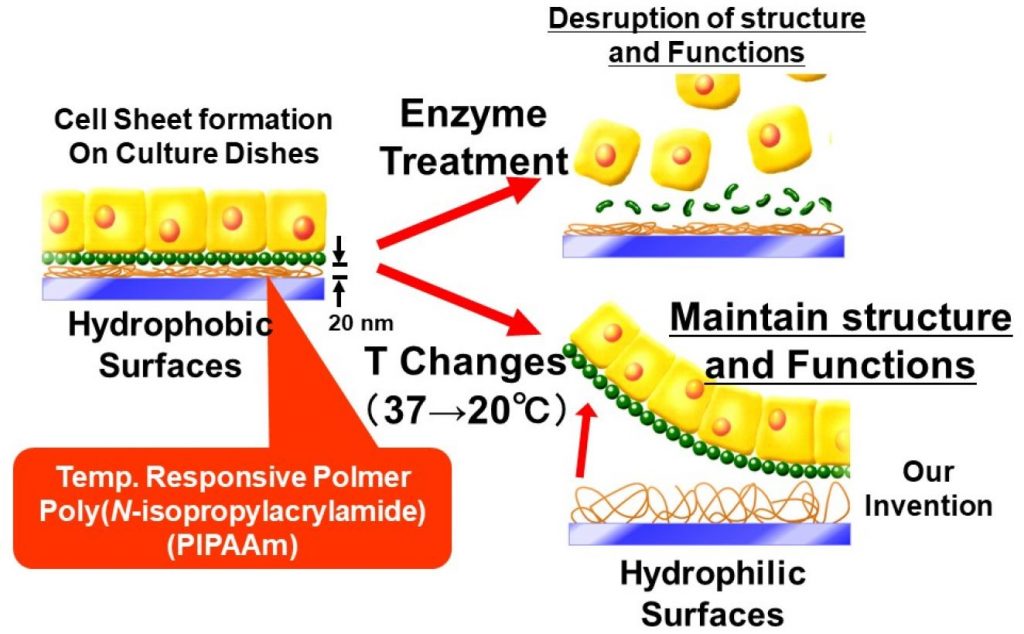

In 1989, Prof. Okano et al. have developed a temperature-responsive culture dish with a uniform 20-nm film of a temperature-responsive polymer, poly(N-isopropylacrylamide) (PIPAAm), by electron beam polymerization. A temperature-responsive culture dish UpCell® has been marketed globally. On this culture dish, cells are cultured at 37 °C and monolayered, and then cell sheet can be harvested with maintaining its biological structure and function by lowering to 20 °C. This invention allows cell sheet to be transplanted to living organs and/or constructed three-dimensional layered tissues.

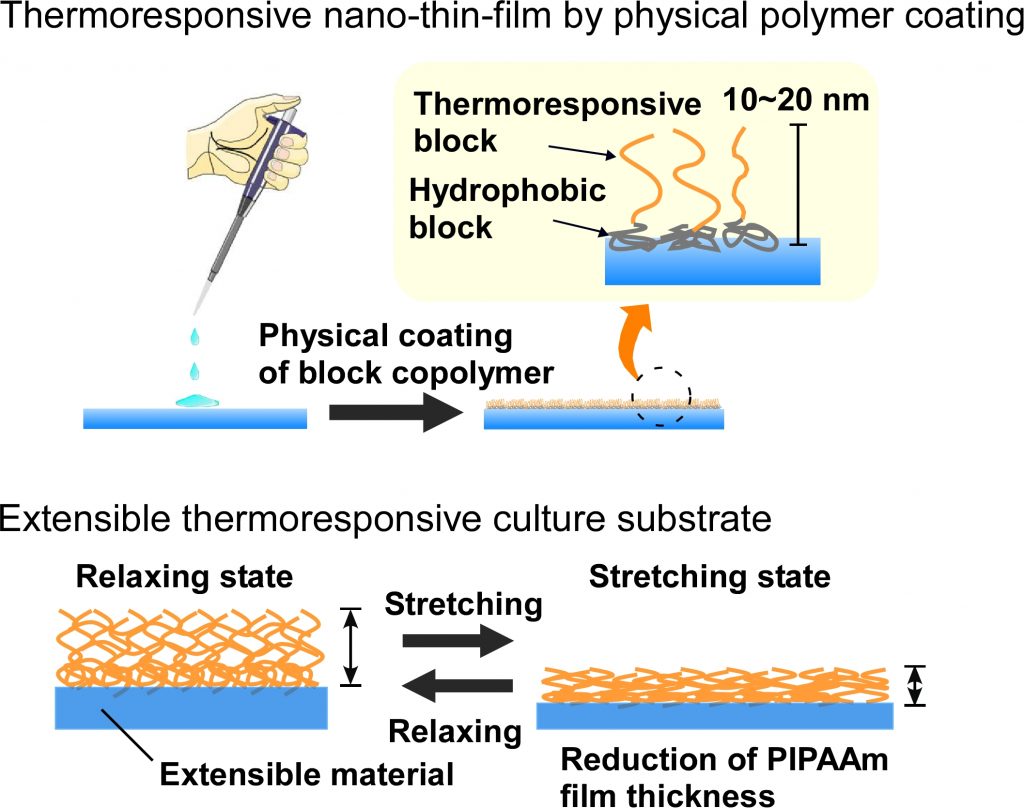

Currently, our institute is promoting to develop the production method of temperature-responsive culture dishes for mass production by reducing manufacturing costs without using an electron beam irradiation equipment. We successfully form a stable temperature-responsive nano-thin film on substrate surface in water by physically surface coating with a block copolymer consisting of both a temperature-responsive block and a hydrophobic block. This method allows the film thickness to be easily controlled at the nanoscale, and the surface can be customized for each cell type with a different cell adhesion property.

Extensible culture substrates modified with temperature-responsive polymers are also developed. Adhesion and detachment of cells were accelerated by changing the thickness of temperature-responsive polymer thin film by stretching/relaxing of base material and using it together with the temperature change. In addition, it is possible to periodically stretch/relax stretchable substrate, which is expected to be applied to the production of cell sheets with cell alignment and/or improved their biological activities.

Creation of next-generation temperature-responsive culture dishes for resembling nano/microscale native structures

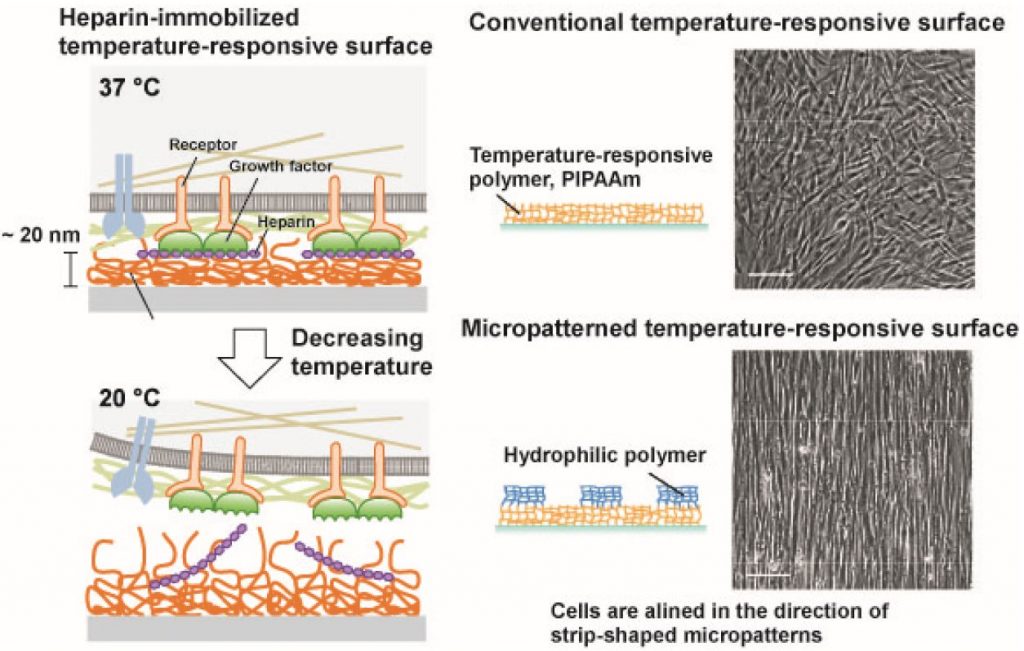

In order to construct three-dimensional cellular tissues resembling native microstructure, we are developing next-generation temperature-responsive culture dishes in combination with nanometer-scale molecular design and microfabrication technology. Temperature-responsive culture dishes modified with heparin, a one of proteoglycans on extracellular matrices and cell membrane, hold heparin-binding growth factors and improve the stability and activity of the growth factors, resulting in the maintenance of liver-specific functions of cultured hepatocytes (eg. albumin secretion). In addition, the cultured hepatocytes are able to be recovered as a contiguous sheet only by lowering the temperature. These sheets are considered to have a potential to provide transplantable liver tissues for the treatment of liver diseases such as hemophilia, as well as an in vitro tissue model for drug screening.

In vitro construction of complex microstructures such as alignment in muscular tissues is important for exhibiting their unique functions in living body, because the aligned muscle fibers exert mechanical functions such as muscle contraction. Cells are able to be aligned on 50 μm-line-and-space striped temperature-responsive surfaces grafted with two types of temperature-responsive polymers with different cell adhesiveness. Furthermore, by reducing temperature, the aligned cells are collected as a single cell sheet, which are able to be layered into three-dimensional tissues while maintaining the orientation. This approach is expected to be useful for the regeneration of skeletal muscle, myocardial, and ligament tissues where orientation structures are essential elements.